Diamond (PCD) Router Bits have become indispensable tools in machining due to their exceptional cutting performance, durability, and versatility. With their diamond-tipped construction, these tools offer unique advantages for woodworking and composite materials. In this blog post, we will explore the benefits of diamond (PCD) tooling including their applications in trimming, profiling, and parting out a variety of materials.

Table of Contents

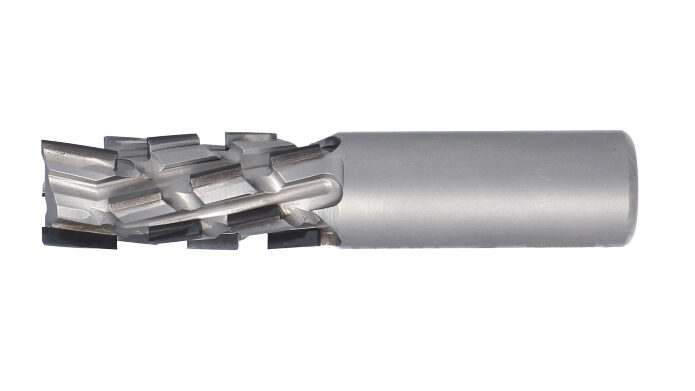

Diamond (PCD) Router Bits

Diamond (PCD) router bits are renowned for their durability and longevity. The diamond-tipped cutting edges of these bits can handle tough materials, including hardwoods, composites, solid surface, fiberglass, and laminates, with ease. Diamond (PCD) router bits provide exceptional heat resistance and wear resistance, resulting in extended tool life and reduced downtime for tool changes. Whether you’re working on intricate profiles, dados, or general shaping, diamond (PCD) router bits deliver precise and clean cuts, even in demanding applications.

Two-Flute Diamond (PCD) Router for Composites

Two-flute diamond (PCD) routers are specifically engineered for machining composite materials. The diamond-tipped cutting edges provide exceptional cutting performance and extended tool life. The two-flute design enhances chip evacuation, reducing the risk of material delamination and improving surface finish. Whether you’re working with carbon fiber, fiberglass, or other composite materials, two-flute diamond (PCD) routers ensure precise and clean cuts.

Three-Flute Diamond (PCD) Router Bits

Three-flute diamond PCD router bits offer enhanced performance and efficiency in CNC machining. With their additional flute, these router bits provide increased chip evacuation and reduced cutting forces. The diamond-tipped cutting edges ensure clean and accurate cuts in various materials. Three-flute diamond PCD router bits are ideal for high-speed machining operations and can handle demanding applications with ease.

Compression Diamond (PCD) Router Bits

Compression diamond PCD router bits are designed to provide clean and chip-free cuts in materials like laminates, veneers, and plywood. The combination of upcut and downcut flutes ensures both top and bottom surface finishes. The diamond-tipped cutting edges minimize material tear-out, making them suitable for applications where edge quality is crucial. Compression diamond PCD router bits are widely used in abrasive panel processing, cement fiberboard processing, cabinetry, furniture production, and high-end woodworking projects.

Opposite Shear Diamond (PCD) Router Bits

Opposite shear diamond (PCD) router bits feature a unique design that minimizes tear-out and produces clean cuts, especially in cross-grain cutting and end-grain routing. This tool geometry is exceptionally adept at processing solid surface materials. These router bits are particularly effective in woodworking applications where achieving a flawless finish is crucial. The diamond-tipped cutting edges of opposite shear diamond (PCD) router bits ensure extended tool life and superior cutting performance.

Diamond (PCD) router bits offer significant advantages for CNC machining, delivering exceptional cutting performance, durability, and precision. With their diamond-tipped construction, these router bits can handle a variety of materials