Table of Contents

Woodworking is a craft that requires precision, flexibility, and the right tools to achieve the best results. Among the essential tools for creating frame-and-panel constructions are stile and rail cutterheads. For woodworkers seeking enhanced versatility and superior performance, the QIC Tools Adjustable Stile and Rail Insert Cutterhead Set stands out as an exceptional choice. This blog post will delve into the advantages of using this adjustable set, particularly focusing on the use of carbide inserts versus brazed carbide and corrugated steel, and will highlight its technical usages compared to non-adjustable versions.

Technical Usages: Adjustable vs. Non-Adjustable Stile and Rail Cutterheads

Adjustable Stile and Rail Insert Cutterhead Set

The adjustable stile and rail insert cutterhead set offers significant advantages for woodworkers who demand flexibility and precision in their projects. This set allows for easy adjustments to accommodate different wood thicknesses and profile variations, providing a customized fit for each project.

Key Benefits:

- Versatility: With the ability to adjust the cutterhead, woodworkers can work with a variety of material thicknesses without needing to switch tools. This is particularly useful for custom cabinetry and furniture making where different panel sizes are common.

- Precision: Adjustability ensures that each cut is perfectly aligned, resulting in tight and secure joints that enhance the structural integrity and aesthetic appeal of the finished product.

- Efficiency: The adjustable design reduces setup time, as woodworkers can quickly make changes to the cutterhead settings rather than swapping out tools. This leads to increased productivity and a smoother workflow.

Non-Adjustable Stile and Rail Cutterheads

Non-adjustable cutterheads are fixed in their settings, designed for specific thicknesses and profiles. While they offer high precision for their designated use, they lack the versatility of adjustable models.

Key Benefits:

- Simplicity: Non-adjustable cutterheads are straightforward and easy to use, ideal for repetitive tasks where the same profile and thickness are consistently used.

- Cost-Effectiveness: Generally, non-adjustable cutterheads are less expensive upfront compared to adjustable versions, making them a good choice for woodworkers with specific, unvarying needs.

Carbide Inserts vs. Brazed Carbide and Corrugated Steel

When choosing between carbide inserts and other materials like brazed carbide and corrugated steel, several factors come into play, including durability, cost, and performance.

Carbide Inserts:

Pros:

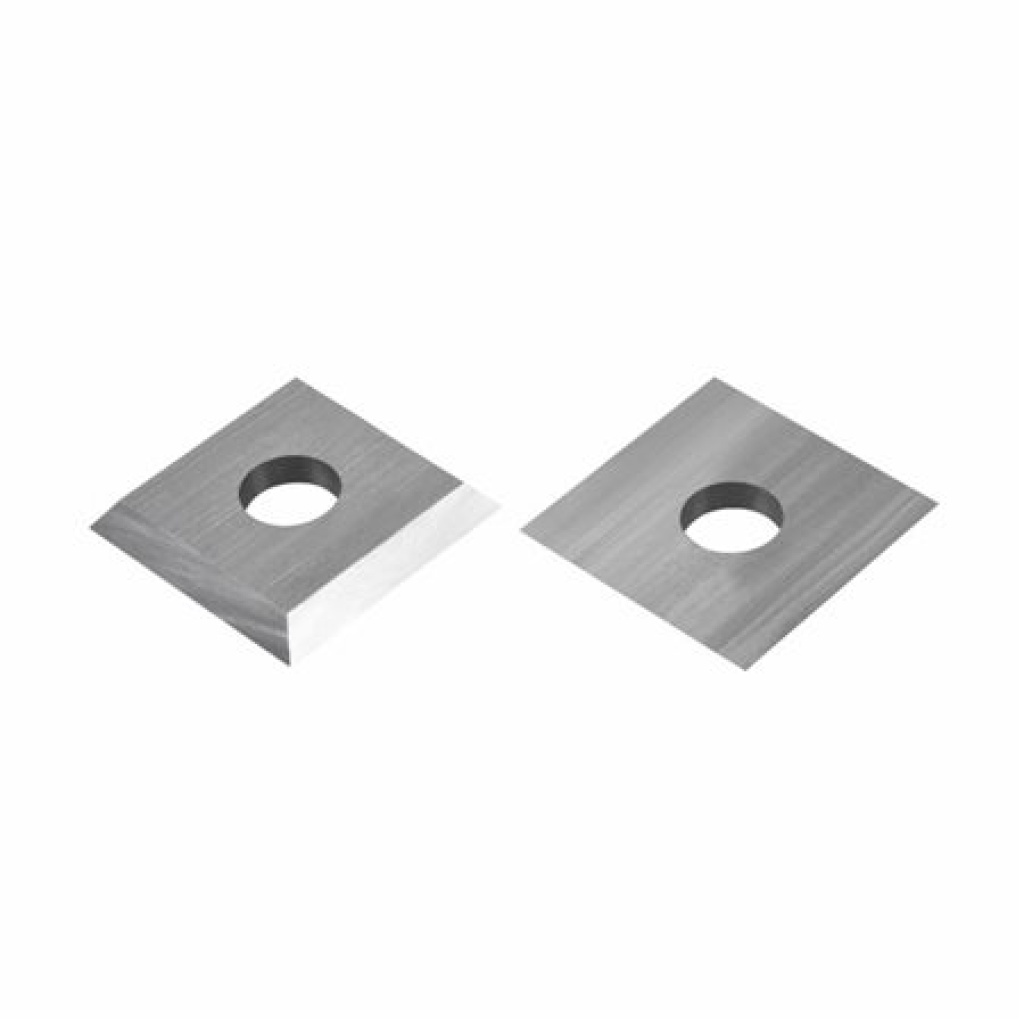

- Durability: Carbide inserts are known for their exceptional hardness and wear resistance. They maintain their sharpness longer than brazed carbide and corrugated steel, making them ideal for extended use without frequent replacements.

- Precision: The consistent quality of carbide inserts ensures precise cuts every time, crucial for detailed woodworking projects.

- Ease of Maintenance: Carbide inserts are easy to replace, reducing downtime and maintenance efforts. This efficiency translates to increased productivity and lower long-term costs.

Cons:

- Initial Cost: Carbide inserts can be more expensive initially compared to other materials. However, their long lifespan and reduced maintenance often justify the higher upfront investment.

Brazed Carbide:

Pros:

- Cost-Effective: Brazed carbide tools are generally less expensive initially, making them accessible for woodworkers on a budget.

- Good Performance: While not as durable as carbide inserts, brazed carbide offers good performance for standard woodworking tasks.

Cons:

- Wear and Tear: Brazed carbide wears out faster than carbide inserts, requiring more frequent replacements and maintenance, which can increase long-term costs.

Corrugated Steel:

Pros:

- Affordability: Corrugated steel is the most cost-effective option upfront.

- Adequate for Light Work: It is suitable for light woodworking tasks and projects that do not demand high precision or durability.

Cons:

- Low Durability: Corrugated steel wears out quickly, leading to frequent replacements and potentially higher long-term costs.

- Inconsistent Performance: The performance of corrugated steel can be inconsistent, making it less reliable for high-precision tasks.

For a comprehensive understanding of the advantages of carbide tools in woodworking, you can refer to Wood Magazine’s guide on carbide tools.

The QIC Tools Adjustable Stile and Rail Insert Cutterhead Set is a valuable investment for any woodworker looking to enhance their precision, flexibility, and efficiency. The use of carbide inserts over brazed carbide and corrugated steel offers superior durability, consistent performance, and long-term cost savings. Whether you’re working on custom cabinetry, furniture, or intricate frame-and-panel constructions, this adjustable set provides the versatility and precision needed to achieve professional results.

By choosing QIC Tools, you’re not just purchasing a tool; you’re investing in the quality and longevity of your craft. For more information on the benefits of using high-quality cutterheads, you can also explore resources from The Wood Database.

Elevate your woodworking projects with the precision and reliability of QIC Tools’ adjustable stile and rail insert cutterhead set, and experience the difference that superior tools can make in your craftsmanship.