QIC's Custom Tooling Process

Concept to Reality - Specialty Tooling Solutions

At QIC Tools we are staffed with experts in all things cutting, clamping, shaping, and profiling. We aim to provide top-tier technical advice while guiding you through the best options available to fit your production needs in an economical fashion. We specialize in tooling for the Wood, Composite, and Aluminum industries. Our offerings include specialized tooling for CNC Machines, Molders, Shapers, Router Tables, Table Saws, Edgebanders, and many more machines and operations. We have the expertise and knowledge to offer the three most commonly used tooling executions, diamond tipped (PCD), carbide tipped, replaceable carbide insert.

The process is quite straightforward and described below.

If you would like a quotation for a custom tool, please fill the contact form below. We can also be reached at (770) 282-1158 Or info@qic.tools

Application Review

During the discovery we go through a series of questions and preferences to understand the application completely. This may involve requesting samples of material, receiving dimensioned drawings of the desired profile. We'll also ask you questions about your target machining parameters and desire for longer tool life.

Quotation Review

With the application review done, we are able to put together a solution that achieves your desired tooling outcome. In the estimate we'll include a few different options that may be suited better for your application or more economical. We will call these options out explicitly.

Order Finalized

Once the order is finalized we will begin the process on our end. An order is finalized by the placement of a PO or payment depending on your account standing or preference

Drawing Approval

We ensure 100% satisfaction, to do this we provide a tooling schematic also referred to as a "drawing" to provide you a visual with dimensions of the exact tool that you will be receiving. At this point, the ball is in your court. You can request changes or approve the drawing as is.

Production and Quality Control

We begin production according to the drawings as soon as the schematics are approved. Following production, we undergo rigorous balancing and inspection to ensure our tooling delivers the quality that you are expecting.

Delivery

We ship the finished tool as soon as the tool is inspected and passes Quality Control. We are experts in getting tooling matched for specific applications and this is why we are able to guarantee our solutions to your machining challenges. .

Available Tooling Executions

PCD Diamond Tooling

Diamond (PCD) Tooling is a workhorse when it comes to abrasive materials. PCD is an excellent choice for materials like Fiberglass, MDF, Laminated Panels, Solid Surface. Diamond (PCD) can be expected to outperform its Carbide counterpart by 20-50 times the life. We can offer PCD solutions for router tooling, saw blades, open bore tooling. PCD tooling can be sharpened numerous times. Regardless of the supplier producing the tools, Always ask how many times a tool can be serviced regardless of the supplier producing the tools.

Carbide Tipped Tooling

Carbide Tipped tooling is a good economical option when it pertains to one-off jobs or low production jobs. Our most frequent Carbide Tipped tools are for matching profiles in historic homes or for wood molding that wasn't a standard offering. These tools are able to be sharpened by face grinding. It's important to note that when a tool is sharpened, the profile will be slightly affected.

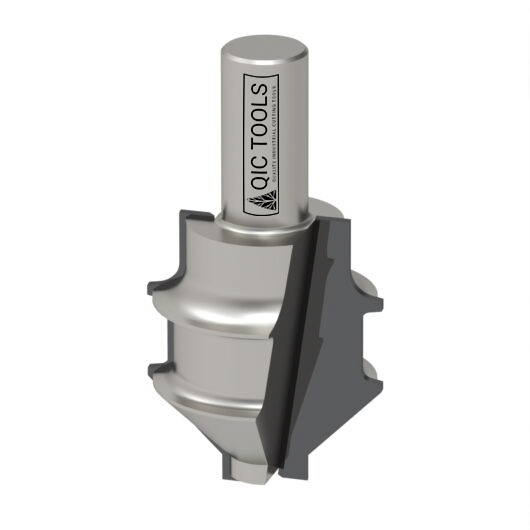

Indexable Carbide Insert Tooling

Indexable Carbide Insert Tooling is an excellent choice when repeatability and strict dimensions come into play. A large benefit of Carbide Insert Tooling is that you pay for the tool body a single time and can order inexpensive inserts and screws when the originals are dull. Carbide inserts can easily be exchanged for new inserts in a matter of minutes saving significantly on down time. Different carbide grades can be offered depending on the material being machined.