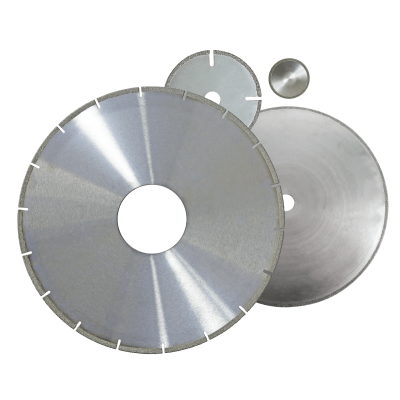

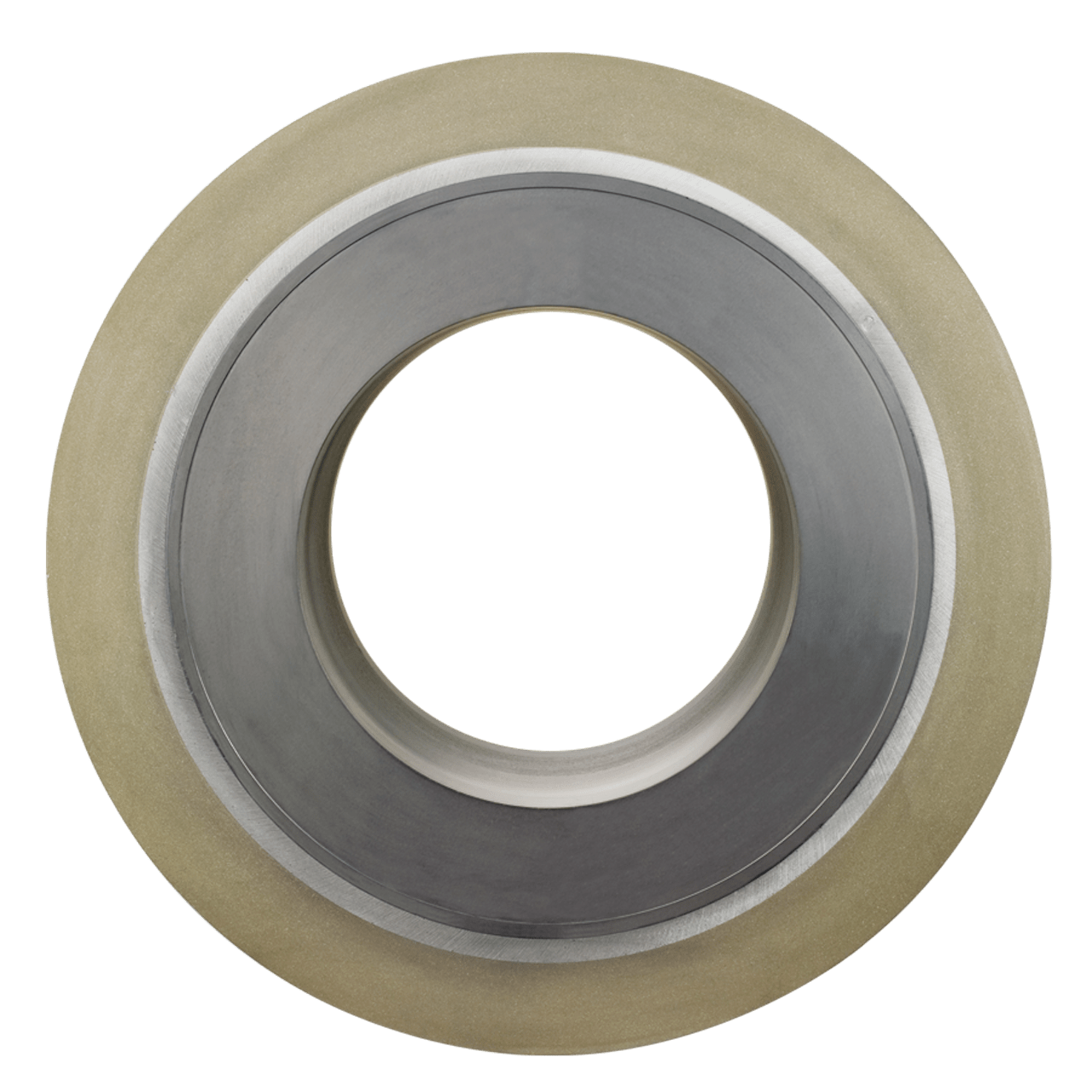

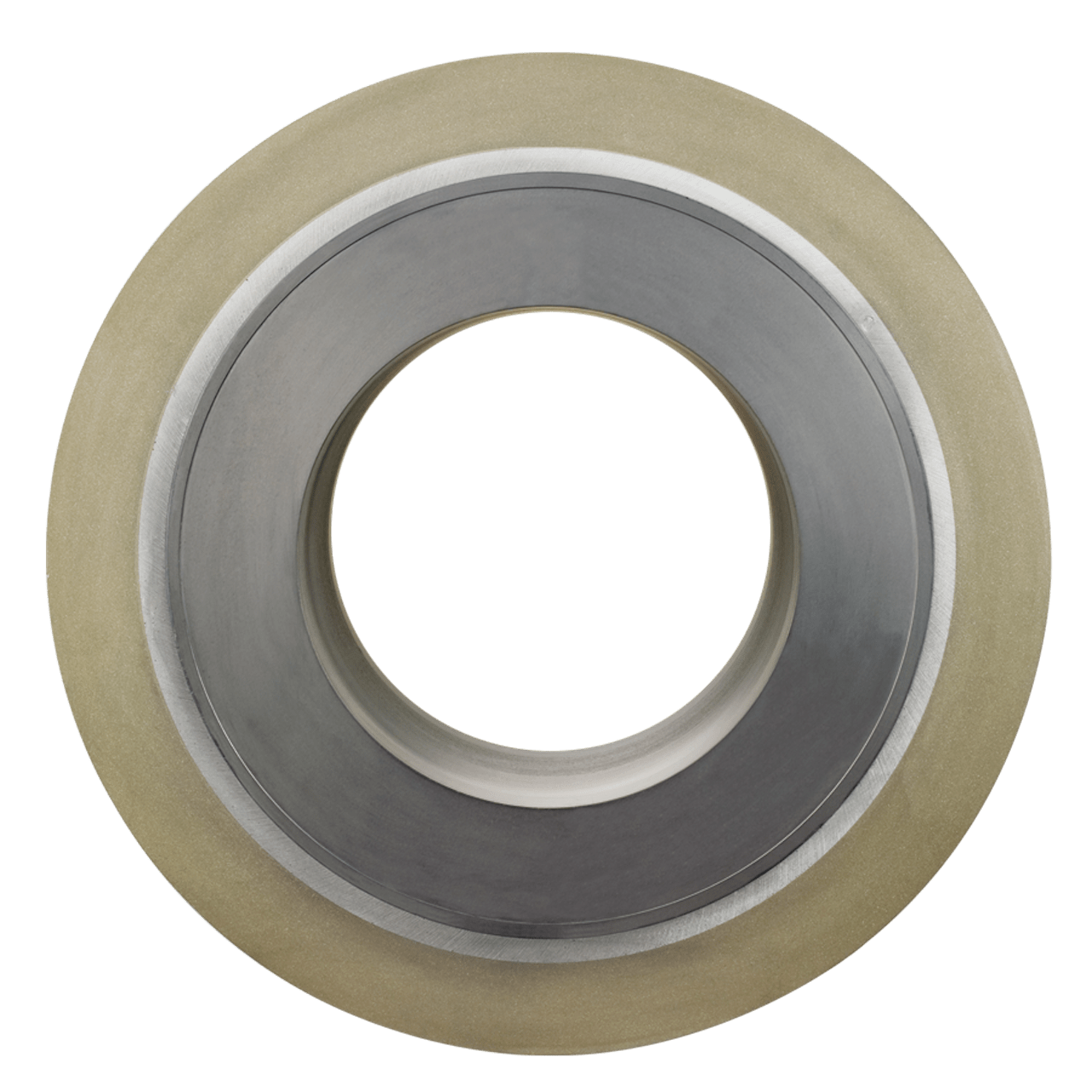

Centerless Grinding wheel

Our custom-engineered wheels are designed to deliver reliable performance when grinding materials like Tungsten Carbide, High-Speed Steel, Ceramics, Glass, and Polycrystalline Diamond. Utilizing our patented VFlex® process, these wheels achieve greater density and eliminate any hardness inconsistencies throughout the section, ensuring optimal performance.

QIC Tools’ centerless grinding wheel is engineered for high-performance applications, offering precision in grinding a range of tough materials. The VFlex® process enhances wheel density, providing consistent grinding results without hardness variations.

These wheels come in both Hybrid Bond and Resin Bond configurations to meet the specific needs of your application. Hybrid Bond is perfect for grinding harder materials, while Resin Bond works best for softer substances.

When you order, your centerless grinding wheel arrives pre-mounted, trued, and balanced on your wheel adapter, ready for immediate use. This minimizes setup time, so you can start grinding without additional preparation.

QIC Tools engineers each abrasive solution to meet your exact specifications. We design the solution to meet the needs of your material and production. We work with you to establish the best solution and then offer pricing. Please reach out to us to discuss your application!