Burr Router Bits

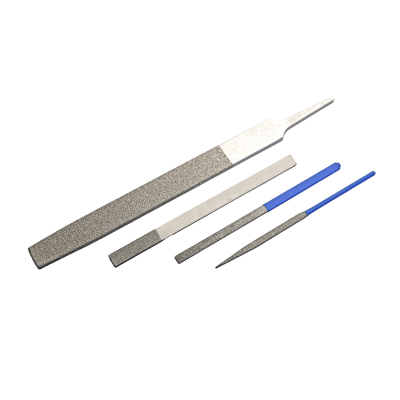

We offer a selection of routers designed for aggressive and precision grinding. These routers can handle a wide variety of materials across various applications.

Our routers cater to grinding needs in industries such as aerospace, defense, and industrial sectors. They are engineered to perform with precision and efficiency across different materials.

I.C.S Braze routers stand out for their versatility. They effectively work with materials like composites, ceramics, and glass. Electroplated routers are specifically designed for tungsten carbide, while PCD/PCBN tooling routers excel at grinding aluminum.

QIC Tools’ routers are built to deliver high performance and reliability in demanding grinding tasks. With numerous options available, we provide the perfect router for every grinding application.

Over the years, our Electroplated technology has been the choice for many professionals dealing with various material grinding needs. The lower initial cost, combined with higher efficiency and longevity, provides an impressive return on investment, making it a cost-effective choice for your grinding operations.

The braze bonding process chemically bonds the crystals to the substrate promoting high diamond exposure with no stripping or peeling.

QIC Tools engineers each abrasive solution to meet your exact specifications. We design the solution to meet the needs of your material and production. We work with you to establish the best solution and then offer pricing.

We are available to get in touch via contact form, email, and telephone

Contact Form: https://qic.tools/contact, Email: info@qic.tools, Phone number: 770.282.1156

Recomended for these materials: Fiberglass, Carbon Fiber Composites, Friction Material, FRP, Graphite, Graphite Epoxy, Honeycombn and other composites.